Principle operation High Performance Adsorption System

High Performance Adsorption System

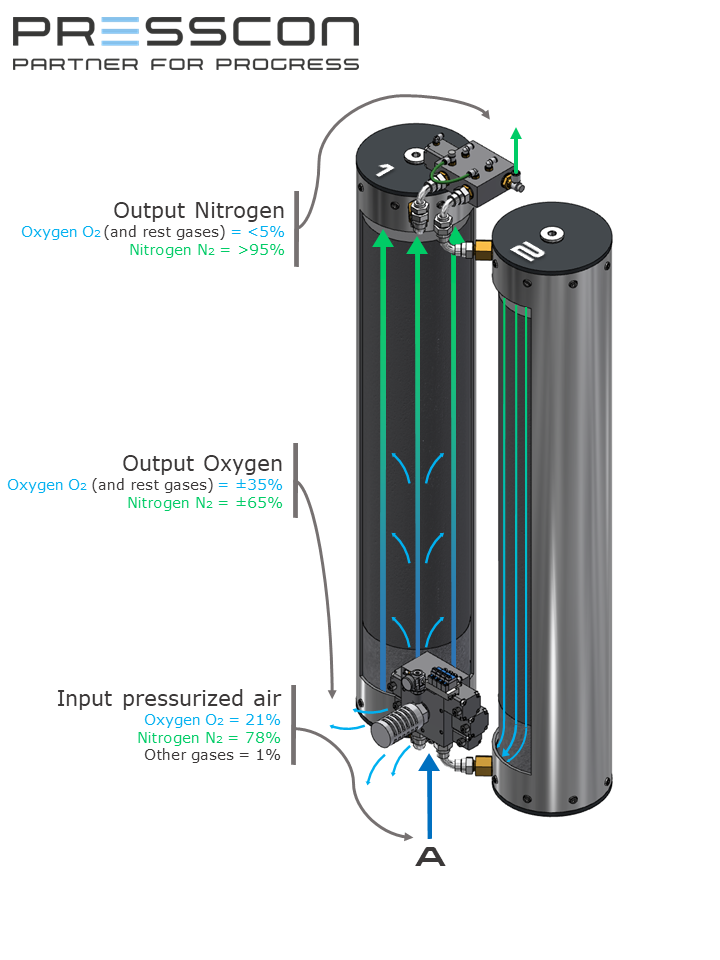

Pressure Swing Adsorption (PSA) is the process that causes compressed air to be converted to a mixture of pure nitrogen. The purity of nitrogen can be set according to the desired application. The compressed air needed for this can be supplied by a dedicated compressor or by an in-house compressor.

PSA process

The PSA process is as follows:

The cylinders are filled with activated carbon. PSA cylinder 1 (left) is pressurized with compressed air. The oxygen molecules are held by the activated carbon and the nitrogen molecules are allowed to pass through. The system consists of two cooperating cylinders. During the process, 1 cylinder is producing nitrogen while the other is regenerating.

HP-PSA system

Based on PSA technology, Presscon has developed its own system that deals with the disadvantages of traditional PSA systems; the High Performance Adsorption system. The HPSA technology distinguishes itself by an optimized air flow in the system and a unique pressure system for the activated carbon. These improvements provide a system that is environmentally friendly with significantly longer life and lower energy consumption. Our patented compression tubes require less than 2m3 of compressed air to produce 1m3 of 95% pure nitrogen.

In addition to low compressed air consumption, this also means that when using a Presscon nitrogen generator, a lower capacity compressor can be used to achieve the desired compressed air flow rate, or the extra capacity of the compressor can be used in another business process. Nitrogen purity can be as high as 99.9999% are set.

Compared to traditional PSA technology, the HPSA offers substantial energy savings of 30%, and when compared to a membrane system, energy savings can be as high as 50%!