Sustainability at Ter Dolen Brewery

Customer case

High purity nitrogen plant and sustainability at Brewery ter dolen

Ter Dolen Brewery, located in Houthalen-Helchteren, Belgium, is a brewery with a rich tradition and a strong focus on sustainability. The brewery has always been committed to innovation and environmental friendliness, but faced the challenge of making its beer brewing process more sustainable while saving costs. The question was simple: “How can nitrogen (N2) help us instead of CO₂?”

The challenge

Traditionally, Ter Dolen Brewery used CO₂ at various stages of their beer production. However, the rising cost of CO₂ and the negative environmental impact of gas production presented the brewery with a challenge. They were looking for a cost efficient and sustainable alternative, and started looking for a way to integrate nitrogen (N₂) into their production process.

The solution

Presscon was engaged to support the brewery in this transition. After a thorough analysis of their processes, a customized solution was delivered:

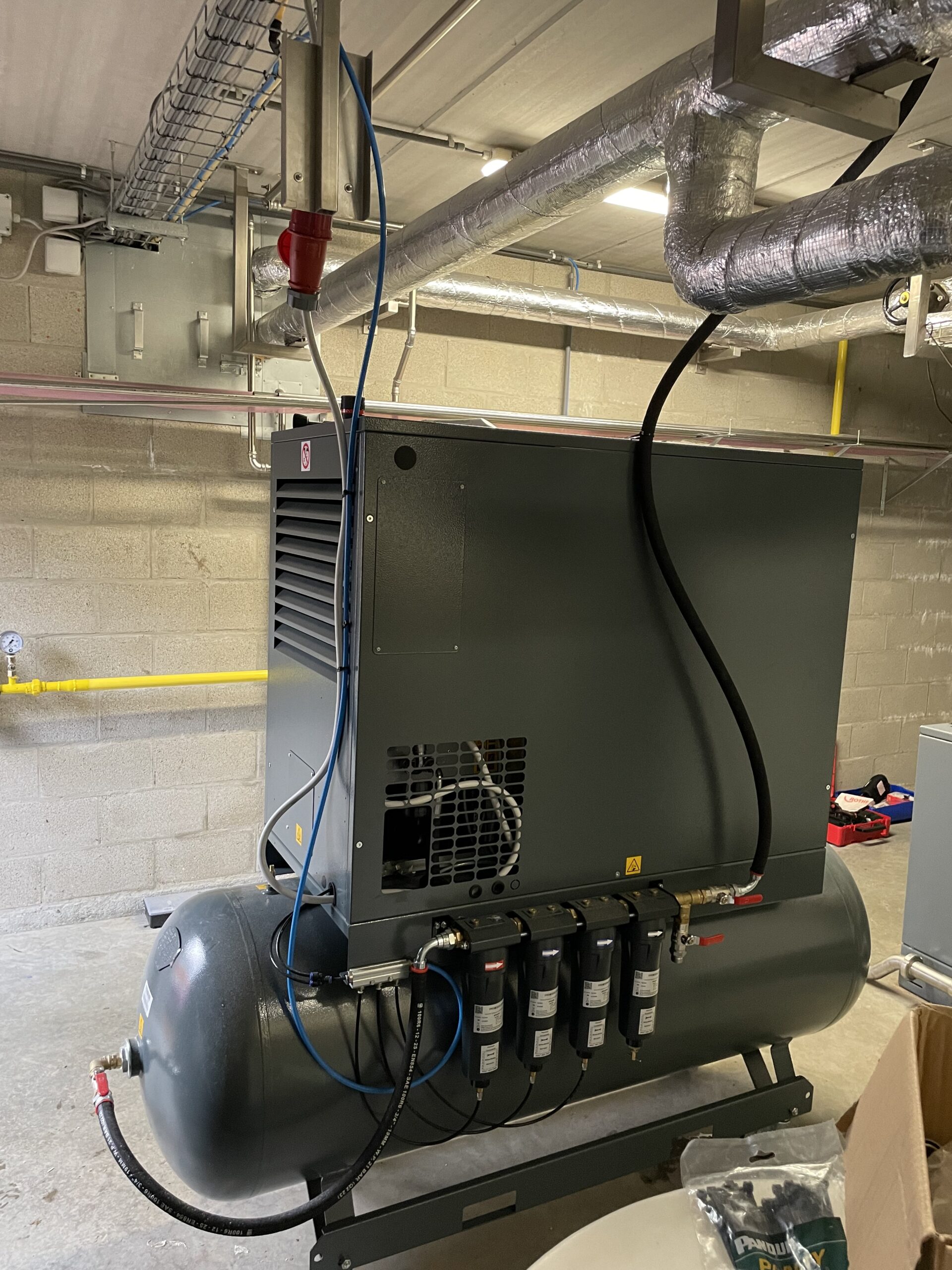

- A compressed air compressor for reliable air supply.

- A nitrogen generator with a purity of 99.99% (100 ppm) to produce nitrogen on site.

- Filters and nitrogen pressure vessels for stable and high-quality delivery of nitrogen (N₂).

This new plant allowed the brewery to replace CO₂ with nitrogen, which not only reduces costs but also benefits the environment.

The switch from CO₂ to nitrogen, what does it mean?

The switch from CO₂ to nitrogen (N₂) in breweries makes the production process more efficient and sustainable. Previously, CO₂ was used for processes such as oxygenating production vessels, pumping over batches (using nitrogen pressure) and oxygenating beer kegs. Now nitrogen is replacing these applications, which not only lowers the carbon footprint but also saves costs. In fact, nitrogen is easily generated on-site, which helps the brewery operate more efficiently while producing more sustainably.

The results

The switch from CO₂ to nitrogen yielded the following measurable benefits for Ter Dolen Brewery:

- Cost savings on the use of CO₂.

- Reduced energy consumption due to the efficient operation of the new plant.

- The investment in the nitrogen plant was fully recouped within 3 years.

- Reliable nitrogen supply improved the consistency and quality of the beer brewing process.

Added Value: White Gas Mixer KM20 ECO

In addition to the nitrogen solution, Ter Dolen Brewery used the Wittgas Gas Blender KM20 ECO, a device for optimizing beer tapping. This gas blender provides several key benefits:

- No oversaturation, preventing waste. Oversaturation can cause foaming and causes unnecessary losses.

- Optimal adaptation of CO₂ content to the beer, which improves the taste and quality of the beer.

- No inventory management of CO₂ as the mixture of nitrogen and CO₂ is produced on site.

- Cost savings through the efficient application of the nitrogen-CO₂ mixture.

The Wittgas Gas Mixer KM20 ECO mixes 70% nitrogen (N₂) and 30% CO₂, giving the beer optimal foam structure and flavor without unnecessary waste.

Conclusion

With the implementation of nitrogen (N₂) and the Wittgas Gas Blender KM20 ECO, Ter Dolen Brewery not only reduced its carbon footprint, but also saved significant costs. These innovative solutions allowed the brewery to optimize its production process without compromising on beer quality. The investment in the nitrogen plant is fully recouped within 3 years, making the sustainable choice financially attractive.

Need advice for your brewery?