Nitrogen Generator

Nitrogen Generators

The technique of expelling Oxygen with nitrogen is our core business. We are specialists in the design, construction and maintenance of innovative solutions with the central core: the nitrogen generator.

A Nitrogen generator is the solution for on-site generation of your own Nitrogen. And is a solution for industries that suffer from unwanted effects of the oxygen molecule. Think of all kinds of professional applications where Nitrogen can be used, such as: corrosion in piping in greenhouses, fire in cold stores and data centers or deterioration of plant and consumer goods by microorganisms.

What is a Nitrogen generator?

A Nitrogen generator can generate nitrogen through compressed air. Nitrogen can be produced at any location. Making nitrogen is done by filtering Oxygen from (compressed) air. We design and build our Nitrogen generators modularly on a skid. We connect the inlet of the generator to a compressed air source (compressor) and connect the outlet to the application’s Nitrogen line. The size of the system depends on the amount of Nitrogen required. For example, we produce the tap generator for use under a bar to tap beer. But we also design and build complex fire prevention systems to create a low-oxygen environment in a fully automatic cooling and freezing house of over 700,000 m3.

Depending on your industry, application and available space, we recommend which Nitrogen generator is best for you! – What is the right Nitrogen generator for your specific needs and requirements.

How does our Nitrogen generator work?

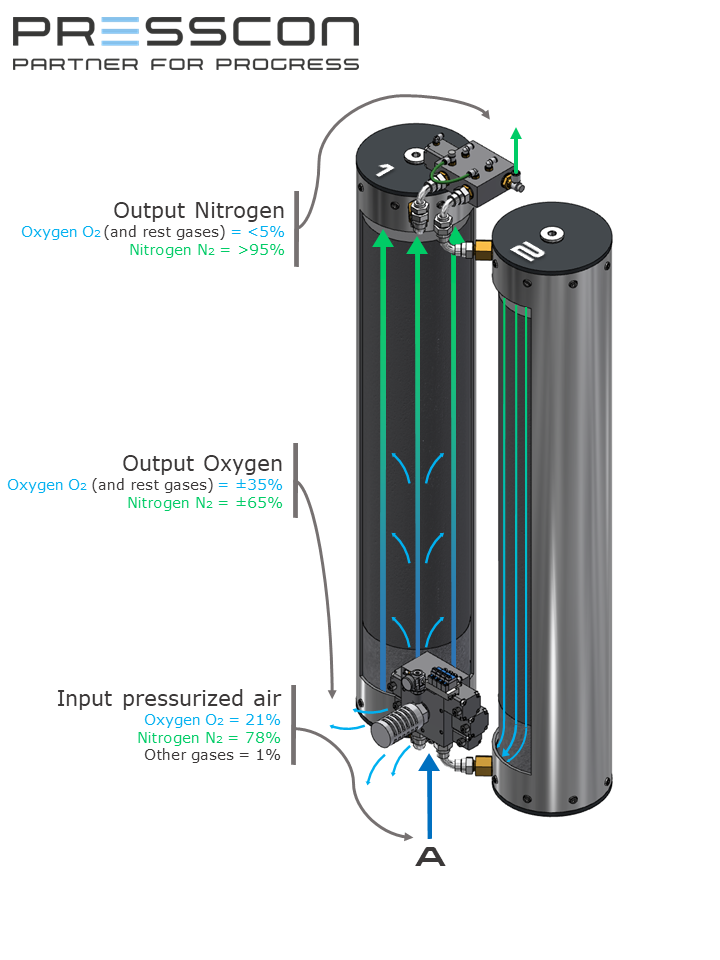

A nitrogen generator generates nitrogen by filtering Oxygen from compressed air. Our Nitrogen generator uses Pressure Swing Adsorption (PSA) technology. In this technique, separation of Nitrogen and Oxygen takes place by binding the Oxygen molecules to a molecular carbon sieve: the Carbon Molecular Sieve (CMS).

Our patented technology

From the existing PSA (Pressure Swing Adsorption) technology, we developed a completely new system: High Performance – PSA. This eliminates the disadvantages of a traditional PSA system. The HP technology is distinguished by an optimized air flow in the system. But also by a unique pressure system for the activated carbon. These improvements make the system environmentally friendly, have a significantly longer service life and lower energy consumption. Our patented compression tubes require less than 2 m³ of compressed air to produce 1 m³ of 95% pure nitrogen.In addition to consuming less energy itself, the generator also functions with a high-capacity or lower-capacity compressor to achieve the desired compressed air volume.

The big advantage of the HP-PSA technology, in particular, is the energy savings. When compared to a membrane nitrogen generator, energy savings of 40 to 50% can be achieved!

How does the HP-PSA technique work?

Our HP-PSA Nitrogen generator uses two columns filled with carbon, which acts as a molecular sieve. Clean, dry compressed air serves as the generator’s power supply and flows alternately through one of the two tubes. In this canister, through hollow fibers, the carbon absorbs Oxygen and other unwanted molecules while the Nitrogen flows freely.

At the moment of saturation, clever control technology depressurizes the tube. This causes absorbed Oxygen molecules to remove themselves from the carbon. At the same time, the other tube feeds compressed air, where the same process takes place. This continues cycle continuously. The pure Nitrogen produced either finds its way directly into the process or is stored in a buffer tank.

Who uses Nitrogen?

Our generators produce nitrogen to expel oxygen. Various industries are affected by the undesirable effects of the oxygen molecule. Examples include corrosion in piping in greenhouses, fire in cold storage facilities and data centers, or deterioration of plant and consumer goods by microorganisms.

Nitrogen can be used for a variety of purposes, such as protecting heating systems in horticulture and buffer tanks. But also for preventing a possible fire and extending the shelf life of food.

Advantage on-site Nitrogen production

Many industries are increasingly making the switch to generating their own nitrogen with a Nitrogen generator. This has many advantages: users always have the amount of Nitrogen needed, the right high purity and the information collected. The desired purity can be adjusted as needed. In the process, one pays no transportation costs and there are no problems with cryogenic storage.

Our Nitrogen generators are developed and assembled in our own factory in Honselersdijk and are characterized by innovation and quality.

Advantages of the Presscon Nitrogen generator

- Modular design

- Low energy consumption

- Long lifespan

- Multifunctional use

What is Nitrogen?

Nitrogen (N2) is an inert gas. An inert gas is a gas that does not enter into a chemical reaction. It is all around us. Of all air, 78% is Nitrogen, 21% is Oxygen and the remaining 1% is made up of various types of other gases. Nitrogen is colorless and odorless and by itself is not harmful to humans and the environment. In the form of Nitrogen oxides or ammonia, however, it can be harmful.

We humans do not use nitrogen, but for many industrial processes it is very useful. There are many different uses of inert gases. Most commonly, inert gases are used to reduce oxygen levels in the air. Sometimes even to negligible concentrations. Because Nitrogen is an inert gas (and does not react easily with most materials), it protects sensitive materials and prevents oxidation, fire and explosions.

The 78% contained in atmospheric air is just not pure enough for these processes. To achieve high purity, you need a Nitrogen generator. With a Nitrogen generator, you produce Nitrogen. The self-made Nitrogen is gaseous Nitrogen. To get liquid Nitrogen, you must first cool and compress it. We don’t deal with that.

OUR NITROGEN GENERATORS

PRESSCON

- Monitor and control air pressure

- Keeps the pressure constant

- Efficient nitrogen cap

- Measure water levels

- ELC - SLC buffer tank measurement

- PLUG & PLAY installation

- Monitor and control air pressure

- Keeps the pressure constant

- Efficient nitrogen cap

- Measure water levels

- Adjustable to desired blow-off pressure

- Modular design

- Low energy consumption

- Long lifespan

- Multifunctional use

- Entirely organic

- Leaves no residue on the product

- On-site nitrogen production and thus not location

- Treatment in bulk possible

Check out other

Presscon products

- Filtering with very powerful magnets

- Visualize contamination with pressure gauges

- Automatic alarms and pressure switching

- Easy to connect to pump systems

- Multiple partial flow filters in one system

- Automatic alarms and pressure switching

- Easy to connect to pump systems

- Visualize contamination with pressure gauges

- +25 years of experience

- Own innovation and production department

- Custom

- Various connection options

- Sustainable and energy-efficient solutions

- +25 years of experience in compressed air

- Own innovation and production department

- Custom

- Sustainable and energy-efficient solutions