PSA nitrogen generator

Many industries, such as greenhouse horticulture, the food industry, breweries, and general manufacturing, face unwanted effects of oxygen. These include corrosion, fire hazards, or the degradation of products caused by microorganisms. Nitrogen offers an effective and safe alternative and is often supplied in gas cylinders. However, these cylinders come with high costs and logistical challenges. That’s why Presscon offers a sustainable solution: on-site nitrogen generation using their in-house developed PSA nitrogen generator, the N-Gen.

What is a PSA Nitrogen generator?

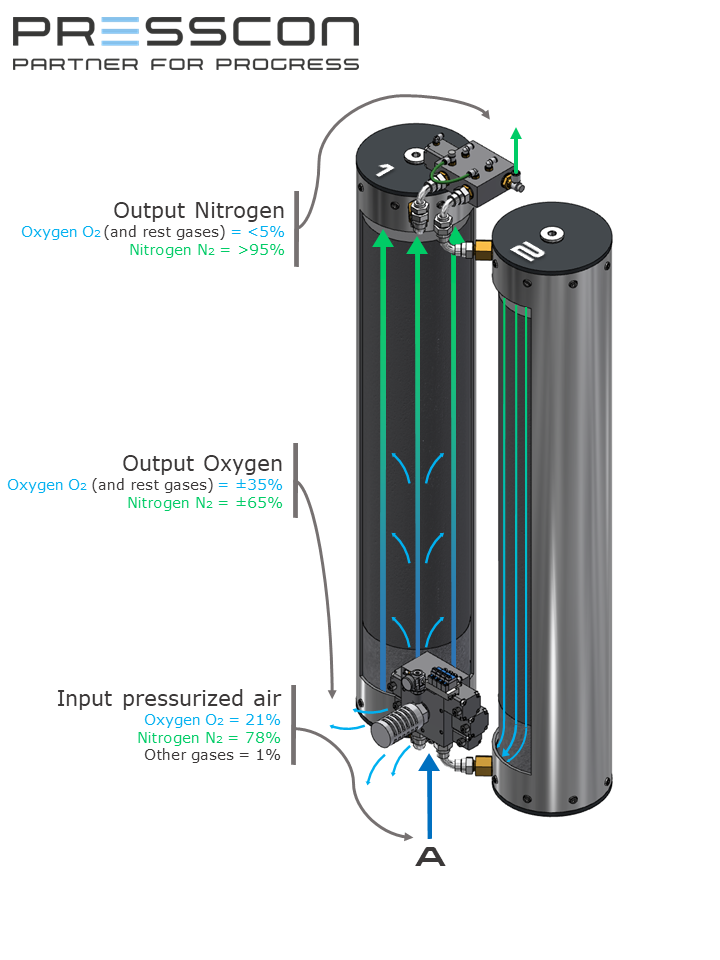

A PSA nitrogen generator is a system that produces high-purity nitrogen gas on-site from compressed air using Pressure Swing Adsorption (PSA) technology. This method takes advantage of the natural composition of air, approximately 78% nitrogen and 21% oxygen, and uses a special material called a Carbon Molecular Sieve (CMS) to selectively trap oxygen molecules under pressure. As the oxygen is adsorbed, nitrogen is allowed to pass through and is collected as a clean, dry gas. This technology offers a cost-effective, reliable, and energy-efficient alternative to nitrogen cylinders, making it ideal for industries that require a continuous supply of high-purity nitrogen.

Need advice about PSA?

How a Pressure Swing Adsorption nitrogen generator works

Pressure Swing Adsorption (PSA) is a gas seperation process used to separate nitrogen from compressed air by selecting adsorbing gas mixture components, primarily oxygen, using an adsorbent material inside a vessel. Here’s how it works step by step:

- Air intake: Compressed air, generated by an air compressor, enters the system.

- Air purification: The air passes through filters and an air dryer to remove water vapor, oil, and dust, ensuring optimal conditions for the adsorption process.

- Adsorption stage: The clean air flows into process vessels filled with Carbon Molecular Sieve. The CMS adsorbs oxygen molecules and other unwanted gases, while allowing nitrogen molecules to pass through.

- Regeneration: Once the adsorbent becomes saturated with oxygen, the pressure is lowered. This causes the trapped oxygen to be released (desorbed) and purged from the system.

- Dual Vessels: PSA units use two alternating adsorption beds. While one bed adsorbs oxygen, the other undergoes regeneration. This setup allows for a continuous operation and stable nitrogen supply without interruption.

Our HP-PSA technology is a completely redesigned version of traditional PSA. It features an optimized airflow design and a patented compression system for the activated carbon. These improvements make the system more environmentally friendly, extend its lifespan, and reduce energy consumption by up to 50% compared to conventional PSA or membrane systems. The nitrogen produced can reach purities up to 99.9999%, which significantly surpasses the performance of standard PSA or membrane nitrogen generators.

Benefits of On-Site nitrogen generation

Cost-effective

Once installed, on-site nitrogen generation significantly reduces recurring costs such as cylinder rental, logistics, and transport. The energy-efficient HP-PSA technology can deliver up to 50% energy savings, resulting in a rapid return on investment.

Independent

With modular, high-redundancy design, each N-gen unit can operate independently. Maintenance can be performed without shutting down the entire system, ensuring maximum uptime.

High purity

PSA nitrogen generators delivers nitrogen with purity levels ranging from 95% to 99.9999% (down to <1 ppm), equivalent to grades 1.5 to 6.0. Ideal for applications requiring extremely clean and dry nitrogen.

Easy to maintain and quickly replaceable

Thanks to a patented compression and filtration system, the N-gen requires minimal maintenance. In the event of a malfunction, the generator can be replaced in under 15 minutes without halting nitrogen production.

User-friendly

Easy to operate and maintain; no handling of heavy or hazardous gas containers.

Sustainable

By eliminating the need for frequent delivery of gas cylinders or liquid nitrogen, on-site generation greatly reduces your carbon footprint. The HP-PSA system also avoids the energy-heavy liquefaction process of traditional nitrogen supply.

Flexible and compact

Our nitrogen generators can be installed horizontally, vertically, on frames or wall-mounted, making them suitable for virtually any industrial environment. The modular design makes them scalable according to your required nitrogen flow and purity levels.

Safe and biological alternative

In sectors like pest control and food packaging, nitrogen is a non-toxic, residue-free solution that replaces chemicals. It’s ideal for applications such as Modified Atmosphere Packaging (MAP) and bulk storage treatment.

On-Site nitrogen generation vs. traditional supply

| Aspect | On-Site Nitrogen | Cylinders / Liquid Nitrogen |

|---|---|---|

| Cost | Low (after setup) | High recurring costs |

| Purity Control | 95 % – 99.9999 % | Limited, supplier-dependent |

| Availability | Always on-site | Delivery-dependent |

| Environmental | Lower CO₂ footprint | High due to transport |

What is a Carbon Molecular Sieve (CMS)?

A Carbon Molecular Sieve (CMS) is a highly specialized form of porous carbon material used to separate gases based on their molecular size. The CMS is engineered with pore sizes that selectively adsorb the smaller oxygen molecules, while allowing the slightly larger nitrogen molecules to pass through. This selective trapping enables the generator to produce high-purity nitrogen gas. The efficiency of the CMS determines the purity and reliability of the nitrogen output. Over time, the CMS undergoes a regeneration cycle, where the adsorbed oxygen is released by lowering the pressure in the vessel. Thanks to its high adsorption capacity and durability, CMS is a key component that makes PSA technology effective and energy-efficient.

Key considerations before choosing PSA Nitrogen gas Generators

While PSA nitrogen generators offer a reliable and cost-effective way to produce high-purity nitrogen on-site, there are several important factors to consider before making an investment.

First, air quality is critical. PSA systems rely on clean, dry, and oil-free compressed air to function optimally and protect the CMS inside the generator. Poor air quality can significantly reduce system efficiency and shorten the lifespan of core components.

The initial investment is another key factor. Although PSA nitrogen generators result in long-term savings, the upfront cost can vary based on capacity, purity requirements, and additional features. It’s important to assess your production volume and application needs to choose a system that aligns with your operational demands.

Ongoing maintenance is required to keep the system running efficiently. This includes scheduled filter changes, performance checks, and occasional inspections to ensure consistent nitrogen output and avoid downtime.

Additionally, space planning is essential. While the PSA unit itself can be compact, the full setup includes a compressor, air dryer, filters, and possibly a nitrogen buffer tank. These components require adequate floor space and proper ventilation.

Finally, for critical applications where nitrogen supply is essential to operations, implementing a backup solution or redundant system is strongly recommended. This ensures an uninterrupted supply during maintenance, unexpected shutdowns, or peak demand.

In summary, PSA nitrogen generators offer a robust, efficient, and scalable solution for on-site nitrogen production, but proper planning and infrastructure are essential to realize their full potential.

Key applications across industries

PSA nitrogen generators are used in a wide range of industries thanks to their modular and flexible design. Units can be configured horizontally or vertically, mounted on frames or walls, and tailored to specific purity and flow requirements, making them suitable for both small-scale and large-scale operations.

Food and beverage industry

PSA nitrogen generators are used in a wide range of industries thanks to their modular and flexible design. Units can be configured horizontally or vertically, mounted on frames or walls, and tailored to specific purity and flow requirements, making them suitable for both small-scale and large-scale operations.

Fire prevention in logistics and warehousing

PSA systems help create oxygen-depleted environments in large-scale storage areas or freezer warehouses, significantly reducing the risk of combustion.

Horticulture and greenhouse systems

Nitrogen is used to protect buffer tanks and heating systems from oxidation and corrosion, ensuring long-term performance and system reliability.

Pest control and microorganism prevention

In agriculture and storage, nitrogen is applied as a biological alternative to chemicals, effectively eliminating oxygen-dependent organisms like gall mites, bacteria, and fungi without leaving any residue.

Why choose Presscon for HP-PSA nitrogen generator

Our generators are powered by our own High Performance PSA (HP-PSA) technology. Based on the traditional PSA principle, we have enhanced it with optimized airflow and a unique compression system for the carbon molecular sieve (CMS). The N-Gen nitrogen generator is designed and assembled entirely in our own factory, which allows us to fully tailor the system to the specific needs of our clients. With less than 2 m³ of compressed air required to produce 1 m³ of nitrogen at 95% purity, the N-Gen is extremely efficient. The unit can be configured to operate based on actual nitrogen demand, ensuring energy-efficient and modular performance. Each unit functions independently, which makes the system scalable and highly redundant. Maintenance or service can be done without interrupting production, each unit can be disconnected or replaced within 15 minutes. We also think ahead when it comes to service: parts are easy to replace, and our technicians are available 24/7 for support.

Why choose Presscon?

With over 25 years of experience and a strong foundation in the Dutch horticultural sector, we have grown into a leading expert in nitrogen solutions across various industries. We develop, assemble, and test all our PSA nitrogen generators entirely in-house at our factory in the Netherlands. This gives us full control over quality, reliability, and customization. We don’t offer one-size-fits-all systems, we deliver nitrogen solutions that are precisely tailored to the specific needs of each customer.

OUR NITROGEN GENERATORS

PRESSCON

- Monitor and control air pressure

- Keeps the pressure constant

- Efficient nitrogen cap

- Measure water levels

- ELC - SLC buffer tank measurement

- PLUG & PLAY installation

- Monitor and control air pressure

- Keeps the pressure constant

- Efficient nitrogen cap

- Measure water levels

- Adjustable to desired blow-off pressure

- Modular design

- Low energy consumption

- Long lifespan

- Multifunctional use

- Entirely organic

- Leaves no residue on the product

- On-site nitrogen production and thus not location

- Treatment in bulk possible

Questions about PSA nitrogen generation?

Presscon specializes in the design, construction, and maintenance of nitrogen expansion systems, fire prevention systems, and innovative solutions with compressed air and nitrogen. Want to know more? Contact Presscon for more information.

Frequently asked questions

Can PSA nitrogen generators replace bottled or liquefied nitrogen completely?

Yes, in many cases. PSA nitrogen generators offer continuous operation and can meet the required purity and flow rate for most industrial processes. This eliminates the need for nitrogen cylinders or liquefied nitrogen, significantly reducing operating costs and environmental impact.

How does air quality affect PSA nitrogen generator performance?

Poor air quality (e.g. with water vapor or oil) can damage the adsorbent containing vessel and reduce the effectiveness of the adsorption processes. An air dryer and pre-filtration are essential to maintain constant temperature, preserve the pore structure of the CMS, and ensure long-term performance.

What determines the nitrogen purity in PSA units?

Nitrogen purity depends on several factors: the flow rate, the performance of the adsorption beds, the regeneration process, and system design. High-quality CMS, consistent pressure, and proper adsorbent material maintenance are crucial to achieving required purity levels.